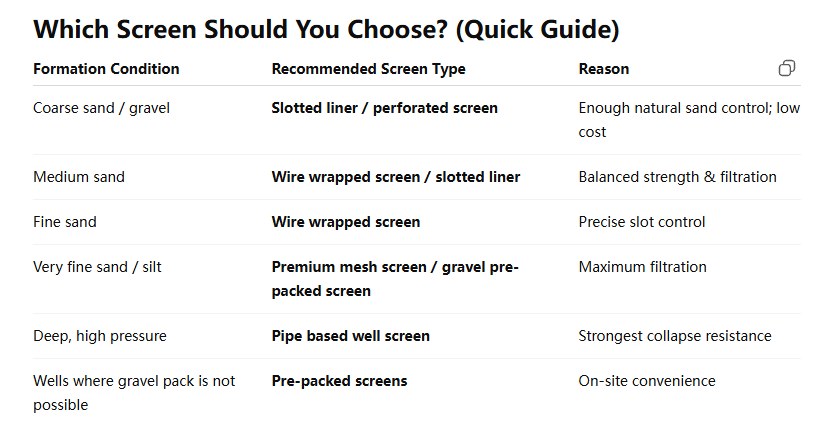

Selecting the proper sand control screen is one of the most important decisions in water well design. The wrong screen can lead to sand production, pump damage, reduced yield, or even total well failure. Below is a comparison of the most common screen types and how to choose the best one for your well.

1. Wire Wrapped (Johnson Type) Well Screens

Best for:

- Fine to medium sands

- High open area requirements

- Long service life

- Municipal / industrial wells

Advantages:

- Continuous slot design ensures excellent filtration and stable flow.

- High collapse strength.

- Customizable slot size from 0.1–3 mm.

Choose if: Your formation is unconsolidated and you need precise sand control + high efficiency.

2. Pipe Based Well Screens

Best for:

- Deep wells

- High-pressure conditions

- Wells requiring heavy-duty strength

Advantages:

- Base pipe (API casing/tubing) provides strong mechanical support.

- Outer wire wrap or mesh ensures filtration.

- Suitable for deep, challenging formations.

Choose if: Your design requires both filtration and high collapse pressure resistance.

3. Perforated Screens

Best for:

- Coarse formations or gravel-packed wells

- Low-cost applications

- Shallow wells

Advantages:

- Simple structure and lower cost.

- Suitable as a support pipe inside gravel-packed designs.

Choose if: Sand is coarse and natural development is sufficient, or when used as the inner pipe in a gravel pack.Stainless Steel Perforated Screens

4. Slotted Liners

Best for:

- Medium to coarse sand

- Water wells and geothermal wells

- Large-diameter wells

Advantages:

- Slot width from 0.2–6 mm

- Good strength and customizable patterns

- Low plugging risk

Choose if: You need moderate sand control with high strength and simple design.

5. Gravel Pre-Packed Well Screens

Best for:

- Very fine sand

- Wells with severe sand problems

- Situations where on-site gravel packing is difficult

Advantages:

- Pre-packed with graded gravel between two screens.

- Excellent sand retention and minimal plugging.

- Saves installation time.

Choose if: Your formation contains ultra-fine particles and requires maximum sand control performance.

6. Premium Mesh Well Screens (Metal Mesh Sand Control Screens)

Best for:

- Very fine formations

- High efficiency wells

- Oil & gas sand control applied in water wells

Advantages:

- Multi-layer metal mesh filtration

- High plugging resistance

- Uniform pore size distribution

Choose if: You need precise, high-efficiency filtration for very fine sand or wells with high production.

Conclusion

The best sand control screen depends on your formation, depth, budget, and desired well performance.

- General use: Wire wrapped screen

- High-strength deep wells: Pipe based screens

- Budget or coarse formations: Perforated / slotted

- Very fine sands: Pre-packed or premium mesh

- Difficult gravel packing operations: Gravel pre-packed screens